6 things I learned at LEGO House Virtual Fan Day

LEGO House (Virtual) Fan Day offered a rare opportunity to learn how The LEGO Group works—these were the most interesting topics in the 3.5 hour session!

For the last several years, The LEGO House has sponsored a special day of talks and interviews for Adult Fans of LEGO. While it’s meant to be an in-person event on the same weekend as the Skaerbaek Fan Weekend, COVID-19 forced The LEGO House to re-imagine it as a virtual event.

The upside of a virtual event is that fans from around the world were able to participate (including me)! Rather than transcribing all of the talks and Q&A, I’ve highlighted the most interesting things that I learned during the 3.5 hour event, with excerpts from several of the LEGO employees who participated. I hope you learn something new, too!

1. LEGO produces about one set per year, per designer

We heard from Poul Schou, the Senior Vice President of Product Design who is responsible for about half of the LEGO sets produced each year.

Poul explained that there are about 400 designers at LEGO and a portfolio of around 400 new sets each year. While that that works out to an average of one set per designer per year, the design process is much more collaborative than that. Designers typically partner on many different sets, and only take the leading role on one or two projects per year. In total, there are about 1800 people working on new sets at LEGO when you include people working on packaging, communications, instruction design, and other roles!

2. New themes target a minimum of two years worth of sets

Poul explained that he helped develop the initial LEGO Ninjago theme after a trip to Japan in 2007. Their original goal was to outsell the “Atlantis” theme, and like most themes, they only originaly planned for two years of sets. (Ninjago was a huge success; tripling the sales of Atlantis in their first year!)

He explained that they typically design two years worth of sets, but some themes like Nexo Knights do not gain the popularity they hoped for and are discontinued before all of the originally planned sets are released.

3. It takes more than a year to develop instructions for the largest LEGO Sets.

The third session was with Kim Yde Larsen, Nanna Mazanti Drejer Friborg and Thomas Folit who work on the Building Instructions team. The team includes 60 people, with about half working on printed instruction manuals.

During the session, we learned that the earliest LEGO buiding instructions were created by hand, followed by multiple digital tools which are used to this day. It was also interesting to learn that the team could produce more realistic renderings of each step, but they “hold the look of the instructions very dear.” They continued by explaining that more realistic instructions are not necessarily easier to follow. They also explained that DUPLO instructions are more realistic than LEGO instructions because they found that it helped younger kids be more successful.

The team responsible for building instructions is involved early in the design process, and after the product has been released to customers.

Even though their team has only around 30 people working on printed instructions (for around 400 products a year), I was surprised to learn that a single employee will work on the largest sets for over a year to develop the building instructions and validate that they result in a great building experience!

One last detail that I’m glad they discussed was the importance of making sure that even the biggest and most complex sets have clear building instructions that any adult can follow. That’s because some adults buy a set because they have an affitity for a brand like Porsche, even though they aren’t very experienced LEGO builders.

More like this?

Subscribe to the Brick Architect newsletter for early access to exclusive content, the latest articles, and updates to the Printable LEGO Brick Labels, LEGO Storage Guide, and my book The LEGO Architect.

4. Star Wars minifigs are “missing” more often than City minifigs

The last session was with Bjarke Schønwandt, quality director on the Consumer-Perceived Quality team.

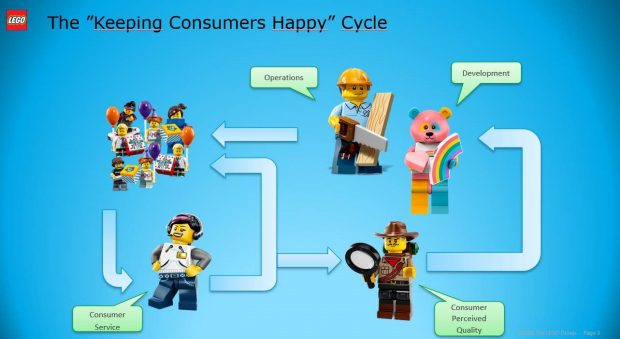

Perhaps my favorite session was the final talk with Bjarke. Why Perceived Quality as opposed to a more objective assesment of quality? “Because we listen to our customers.” That’s why his team focuses on what they call the “Keep Customers Happy” cycle.

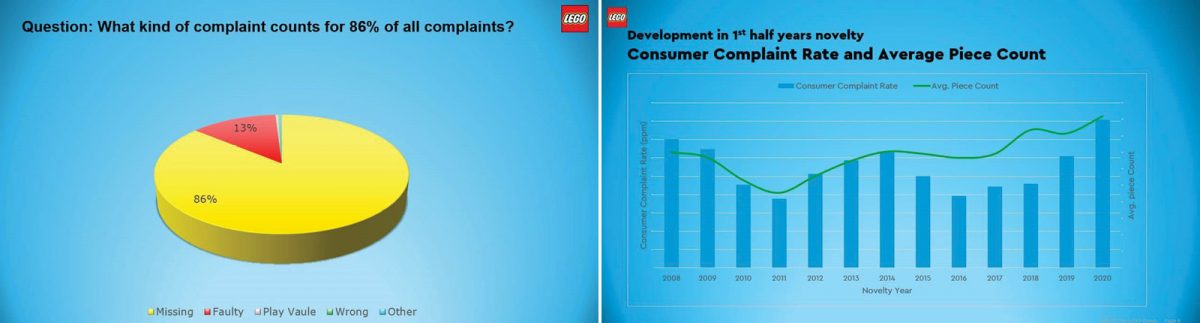

It turns out that the vast majority (86%) of customer service issues are caused by missing parts, and that the significant increase in average part count in recent years is loosely correlated to the customer complaint rate.

The fun surprise in his presentation was how much more frequently families call Customer Support about missing minifigures in popular themes like Star Wars, than unlicensed properties like City. To his credit, he doesn’t blame parents for intentionally lying about missing parts, accepting that highly sought minifigures may get taken by another family member, lost at school, or experience similar unfortunate outcomes. (They seem to understand that good customer service is important to maintain brand loyalty.)

5. Colorant (Pigment) can get burned in the mould and change color

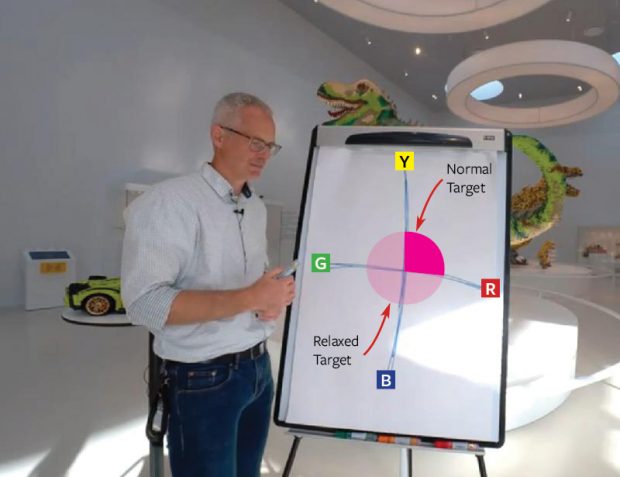

Bjarke explained that their target for each pigment is usually within a narrow range in one quadrant of the color space, but they had to relax their target while working through supply chain issues. (Illustration re-created from my memory.)

The more surprising thing that we learned is that pigments can actually burn and become discolored if they spend too much time in the moulds at high heat. This caused the most severe color matching issue in the Sián, which I believe was on part #15100 1/2 Pin w/ Hole. (You can see that the part is significantly darker in this review at Brothers Brick.)

Bjarke went on to explain that this type of issue is caused by a poorly designed mould. (As I understood his brief description, it sounds like the pathways that melted plastic flow through ebfore entering the mould were too long, causing plastic to remain in the metal block for too many cycles before being shaped into a part.) To resolve the problem quickly, they cheated by running the same mould on a faster system!

For a longer read on the topic of Perceived Quality, read this separate interview on New Elementary with Bjarke Schønwandt (from earlier this year.)

6. We shouldn’t expect a lot more co-branded products

Julia Goldin is the CMO and EVP of the LEGO Group. She started off today’s presentations from her office in London.

Julia Goldin re-stated that LEGO is commited to adult fans, both through the new 18+ line, and through strategic partnerships.

She also talked about how the IKEA partnership builds on a specific learnings from their research showing that most families do not have a lot of space for kids to play. That’s why we partnered with IKEA to create boxes that serve dual functions—both as storage and play boxes.

Thanks for sharing that – was cool to learn those facts!

Great article, it’s very interesting to learn the inner workings at the Lego company. It’s great to know WHY Lego ran into such large variations in colour of the lime Sian and perhaps 2021 lots of the car will show much reduced differences.

Did they talk at all about their approach to sets for girls? I’m still hoping they will follow up the Elves theme with something equally as exciting- Dots doesn’t cut it.